About the project

Project objectives

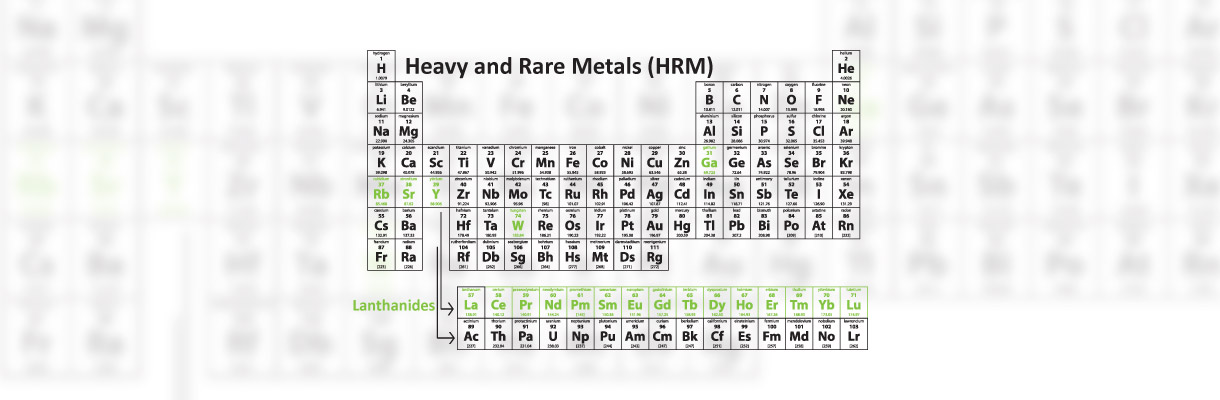

The project aims to demonstrate by a detailed fundamental and applied investigation the technically feasible alternative for strategic metals production as heavy and Rare Metals (HRM) consisting of Lanthanides: Lanthan (La), Cerium (Ce), Praseodymium (Pr), Neodymium (Nd), Promethium (Pm), Samarium (Sm), Europium (Eu), Gadolinium (Gd), Terbium (Tb), Dysprosium (Dy), Holmium (Ho), Erbium (Er), Thulium (Tm), YƩerbium (Yb), Lutetium (Lu), including Gallium (Ga), Strontium (Sr), Rubidium (Rb), Ytterbium (Y) and Tungsten (Wolfram), by utilizing fresh and reuse landfilled fly ash and bottom ash as a source source (pulverized) rock. The proposed approach, with a very limited experience in Europe and even worldwide, demonstrates innovative methods/technologies to develop metal recovery processes and transform wastes into high-grade and valuable metals with various applications, creating the possibility for a fast and low-cost access to strategic metals and a widespread saving of EU primary mineral resources.

The project expects to achieve results to be used as an iniƟal basis for the advanced, waste-less and environmentally safety utilization of various ashes to obtain concentrates, high purity reactives, metals and metallic salts, catalysts and adsorbents, metal and oxide nanoparticles, single or deposited on silica, scale controlled and functionalized and solar collectors precursors manufacturing to be used in high-tech, chemical, environmental and metallurgical purposes.

The project objectives involve: i) experimental models for sampling and characterization of raw materials; ii) inventory and mapping of the residue streams distribution within the selected sites; iii) preliminary preparation of the ashes provided from the industrial dump; iv) experimental sampling and physical haracterization of ash samples; v) analytical solutions for HRM separation and processing by several extraction techniques; vi) synthesis and characterization of high purity reactives, metals and metallic salts, novel nanostructured metal oxides catalysts on various supports; vii) finding solution for reuse the ash wastes remaining after acid treatments; viii) dissemination of results by organising a workshop, preparing scientific articles, patent application, market potential replication.

Project actions

- Technical documentation concerning actual supply (including representative sites selecrion in the networking countries), storage and characteristics of the targeted non-energy industrial wastes

- Mapping the location and the properties of landfilled coal ashes, as an alternative prospective mean to virgin resources and environmentally beneficial route to obtain valuable materials

- Conduct sampling campaigns in targeted sites, selecting and complex characterization of representative samples provided from three different countries and sources

- Identify procedures/methods to separate/recycling/recovery the targeted HRM

- Achieving new ways of recycling ashes to valorize each waste individual characteristics

- Establishing the technical solutions for selection and optimization of the chosen demonstrative laboratory scale flow sheet procedures/methods

- Improvement and elaboration of new technologies for separation of the mixture components and components recovery (oxide nanoparticles, metallic nanoparticles, reactives)

- Assessment of technical-economic feasibility of the proposed separation and recovery procedures/methods

- Obtaining of experimental concentrates, reactive and pure metals, catalysts and adsorbents for depollution purposes, preparation of metal and oxide nanoparticles for the use in High-Tech, in the present case on solar collectors precursors manufacturing

- Complex analysis of the remaining residue and finding ways for valorization / recycling

RareAsh, is focused to comply with the EU priorities by the proposed actions which are innovative (by using recovery methods based on acids and not on cyanides) and have a demonstrative character at laboratory scale, proven by:

- application to non-energy secondary raw materials from Romania and Poland (fly ash, bottom ash, ash and slag wastes from coal fired power plants) in opposition to EU wide produced ash types from globally commercialized coals, such as in Portugal

- application of different separation methods (flotation, hydro-metallurgical, precipitation, ion exchangers, electrolysis)

- new technologies for the obtaining of precursors / products of HRM concentrates, high purity reactives, catalysts, precursors for the alternative power and “green energy” technologies

European context

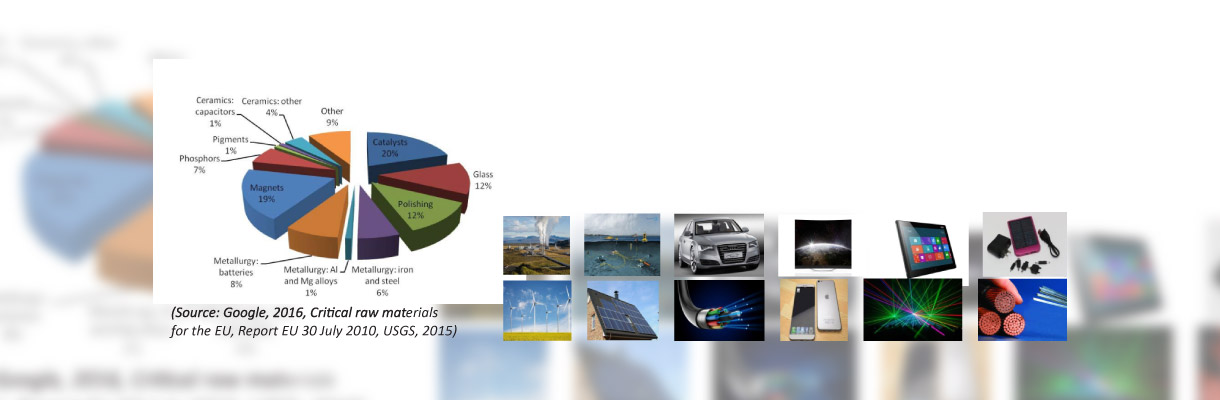

European industries in the automotive, aviation, wind power, photovoltaic and lighting industries, as well as in the high-tech sector as whole, used tons of raw materials each day for their products. However, since its domestic production is limited to 3% of the world production, the EU is highly dependent on the import of many metals used. The EU faces a number of critical issues that can endanger the security of supply of the highly diversified mineral resources needed by its economy. Securing supplies has therefore become crucial. This requires advanced research on the entire value chain of raw-materials, from ore extraction to mineral processing, and from product design to reuse and recycling.

ERA-MIN (www.era-min-eu.org) call is an ERA-NET program on the Industrial Handling of Raw Materials for European industries and is supported by the European Commission's 7th Framework Programme. It was aimed at seƫng up networks and mechanisms to foster research in the field of industrial production and supply of raw materials, in line with the “EU Raw Materials Initiative”.

Topics

ERA-MIN focuses on the issues related to the three segments of the non-energy mineral resources: construction minerals, industrial minerals and metallic minerals.

The topics addressed by ERA-MIN cover the entire raw materials value chain: from primary to secondary resources, substitution of scarce elements, as well as cross-cutting issues like the mitigation of environ-mental impacts and raising public awareness.

ERA-MIN aims at overcoming the current state of fragmentation of research in the field of raw material supply and production by developing convergence and synergies at EU level between national research programs, industry, and with research programs led by the European Commission.

Tasks and objectives

The main objective of ERA-MIN is to foster coordinated research on the entire raw materials value chain.

To achieve these objectives, ERA-MIN is conducting three main tasks:

- Mapping and networking the European nonenergy mineral raw materials research community

- Roadmapping research priorities

- Implementing joint actions and, especially, a joint call

Networking

ERA-MIN creates networks at several levels within the European non-energy mineral raw materials research community:

- Networking between the EU Member States to build common and long-lasting interfaces between industry, research, education and policy-makers

- Networking of national, regional and European research programs to reduce fragmentation and duplication of research.

- Networking of the contrasted European non-energy mineral raw materials research community (ENERC).

An integrated approach to research - the entire raw materials value chain requires the involvement of many skills and varying expertises: Earth, environmental, life, social and material sciences, engineering and processing and knowledge from organisations involved in the recycling, down-stream users of raw materials and economists

ERA-MIN currently comprises 19 partners that are research-funding organisations (15 full members and three associated partners) from 15 countries.

Background

The scope of ERA-MIN is in line with the Europe 2020 aim to achieve smart, sustainable and inclusive growth. As the global population is expected to increase to 9 billion by 2050, resource demands will start to outstrip the capacity to supply some of them in economically, environmentally and socially sound conditions. New technologies in almost any field of daily life will require increasing use of crucial non-energy raw materials. Challenges from the new technologies will additionally affect the demand for non-energy mineral raw materials.

New technologies in almost any area of the daily life will require increasing use of crucial non-energy raw materials, which will also affect the demand for non- energy mineral raw materials. As large, rich deposits located in countries that offer access to their mineral resources are getting rare, research is vital to explore deeper-seated deposits in Europe, deposits in higher risk countries and to develop knowledge on unconventional resources.

The efficiency of material production and use throughout the whole supply chain needs to be improved, turning this chain into a materials circle where waste becomes the resource needed by another process, and dissipation is avoided as much as possible. Additionally, a significant reduction can be achieved by substituting scarce elements by more abundant ones with the same functionalities, or by substituting the functionality itself.

To achieve this, innovative recycling technologies for technology metals from complex products are as important as non-technical innovations to obtain better access to secondary resources and ensure their resource efficient processing throughout the recycling chain.

Project results

Expected results

RareAsh's driving proposed results are related to:

(I) Demand for 21 critical materials as Lanthanides, Scandium, Yttrium, Gallium, Strontium, Rubidium, and Wolfram which is expected to increase since they are needed in the new generation of high-tech materials used by the EU industries;

(II) Recycling large volumes of coal ash waste generated every year cannot be ignored as one of the most promising and potential non-energy secondary unconventional resource of HRM in Europe;

(III) Maximising valuable metal recoveries of the production processes, by choosing of the appropriate methods;

(IV) Environmental goals like combustion waste reduction from landfill sites, reduced mass movement and land use, decreasing CO2 emissions from conventional mining activities;

(V) Contribute to securing a sustainable supply of mineral resources for the EU countries;

(VI) Health and safety aspects;

(VII) Creation of highly skilled jobs and improvement of economic activity.

Environmental

- The utilization and reuse of large volumes of coal ashes generated every year and/or landfilled for HRM extraction purposes, will secure in the future a sustainable supply of critical mineral resources for the EU countries;

- Preserve natural resources, which would otherwise be obtained from natural raw materials by using unconventional secondary resources - fresh and land-filled fly ash and boom ash - the same way as any other source so (pulverized) rock for strategic metals production such as Lanthanides, Ga, Sr, Rb, Y and W;

- Waste-less and environmentally safety utilization of various ashes by residue valorization, and recovery of metals with mineral acids instead cyanides;

- Promoting and contributing for sustainable of waste management and waste zero directives application within the EU, facing lowest remaining reserves and same environmental problems.

Technical-economic

- Utilizing coal waste products (CWP) as secondary resources in EU and winning back materials by recycling waste streams, to make EU less dependent on raw materials from elsewhere, and to save EU natural resources;

- Develop metal recovery processes and transform wastes, enriched in metal concentrations similar to those in some mineral ores, as one of the most promising secondary resource into high-grade and valuable metals with various applications, for which previously the technical and/or economical recovery feasibility was not existing;

- Metal recovery from coal ash may be more efficient than the recovery of metals from mineral ores since the physical form is more amenable to processing by several extraction techniques and processes. Thus, me, energy, environment and economic efforts are considerably reduced;

- Obtaining information about composition/metals distribution in these mineral combustion residues and its physical properties (type of 'rock') and about evolution and overall availability of historic dumps;

- Maximizing valuable metal recoveries of the production processes, by appropriate methods/technical solutions for selection and optimization (precipitation, ion exchange, electrolysis, microemulsion) which will valorize the individual characteristics of each waste;

- Obtaining of HRM concentrates with rare earth high content, as a key intermediary in the production process and a by-product of the HRM extraction process;

- Obtaining of high purity reactives, metals and metallic salts, catalysts and adsorbents, metal and oxide nanoparticles, single or deposited on silica, scale controlled and functionalized and solar collectors precursors that will be possible used in high-tech, chemical, environmental and metallurgical purposes;

- Securing a sustainable supply of HRM for the EU countries when the use of rare earths in high-tech is increasing dramatically and the demand for rare earths will continue to grow significantly.

- Promoting “Eco labelling of secondary resources” to inform potential customers and allow for sustainable procurement.

Social

(1) To contribute to new areas of development, economy reinforcement, high qualified jobs, and EU autonomy and security;

(2) To increase the quality of life in urban and rural areas by reducing the health and environmental impact caused by extraction activities, and landfills;

(3) To increase the people's level of awareness and trust in conserving of natural resources by wastes recycling;

(4) To develop reference documentary for people's awareness on long term environmental raw materials securing supply;

(5) To increase the level of people's trust that recycling offers significant investment, innovation and employment opportunities in the EU.

HRM in combustion waste products (ashes)

Coal forming basins

Coal ashes

- Large volumes of coal burned

- Large volume of coal ashes produced each year

- Large volume of coal ashes disposed by landfilled

- Huge amount of fine grained mineral phases organic matter free that host HRMs

- Increased environmental problems

HRMs

- Concentrations of critical metals in coal ashes is known for decades

- Interesting physical, chemical and mineralogical properties

- Amount of HRMs sometimes as in the Earth’s c rust (hundred ppm)

- Recovery is environmental friendly, fast and low-cost process that saves primary metal resources.

Industrial technologies have been developed to extract Ge from CWP used by different companies in Russia, China and other countries. Under experimental and industrial conditions, the technologies for the extraction of Ga, Mo, Pb, and Zn together with Ge.

The UK has already a full-scale plant, and other countries launched efforts to extract materials from coal fly ash, since the extracted value per ton is over US$1000.

RareAsh – the proof of circular economy concept

Black to Green using Gray requires the transition to a "green economy, circular economy" by connection between economic development, biodiversity, ecosystems, climate change, health and peoples welfare in the medium and long term. By applying the concept of "green economy, circular economy", RareAsh project is aiming:

- New separation solutions in order to prevent excessive use of natural resources for HRMs recovery, with the main objective of reducing environmental risks;

- Long-term alternative to substitute primary raw materials with ash, as secondary raw material, in order to improve quality of life.

Up to date results

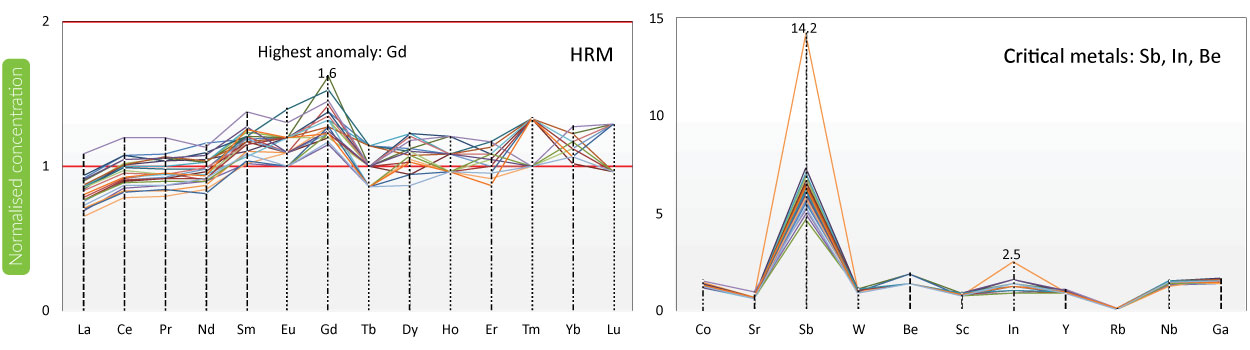

Romanian boom coal ash samples: normalized concentrations of REE and critical metals to the Upper Continental Crust (trace elements determined by ICP-MS).

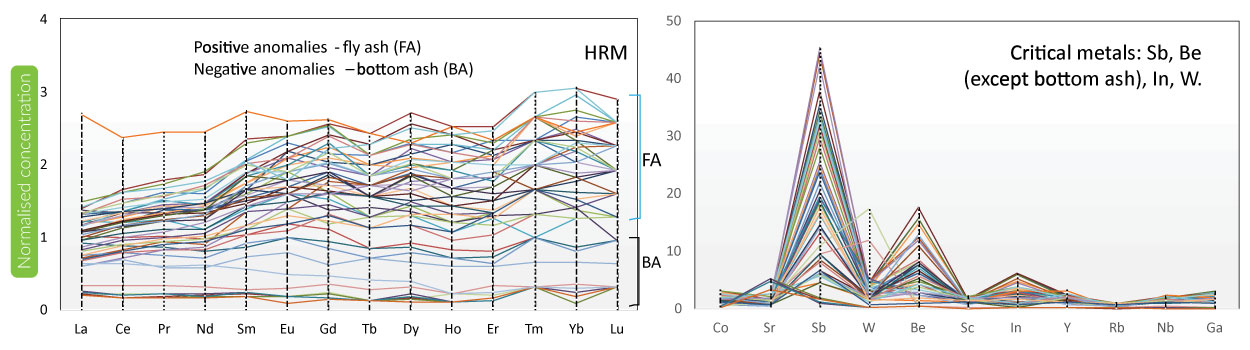

Poland coal ash samples: normalized concentrations of REE and critical metals to the Upper Continental Crust (trace elements determined by ICP-MS).

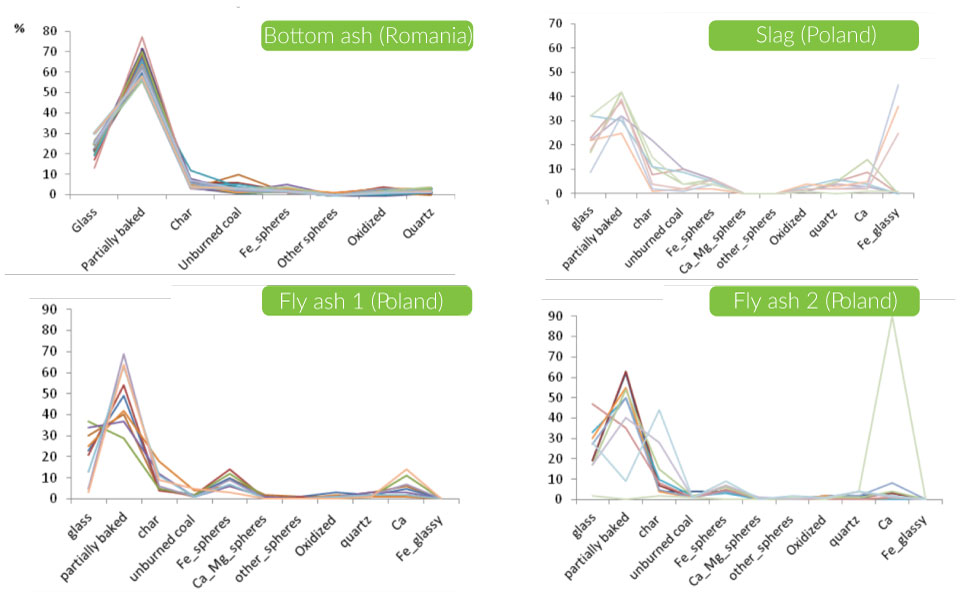

Ash petrography as determined by oil immersion reflected light microscopy (vol.%; average values)

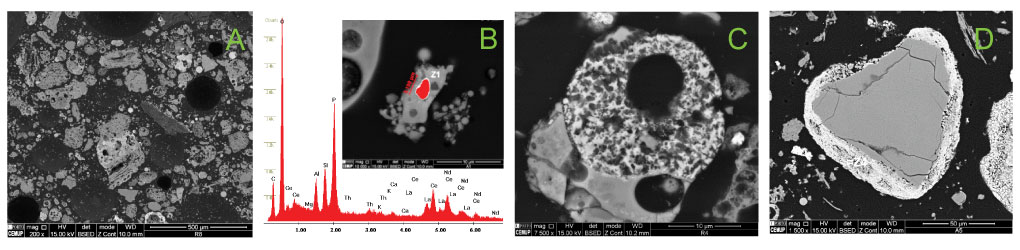

SEM/EDS characterization: ash main phases (A), grain size and composition (B), minor phases (C), combustions characteristics (D)

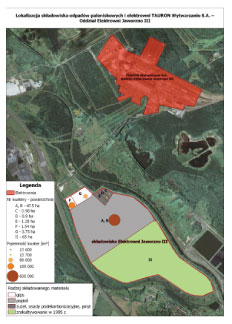

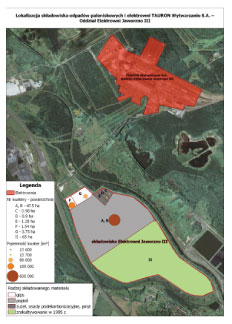

GIG data base of dumps_1

GIG data base of dumps_1

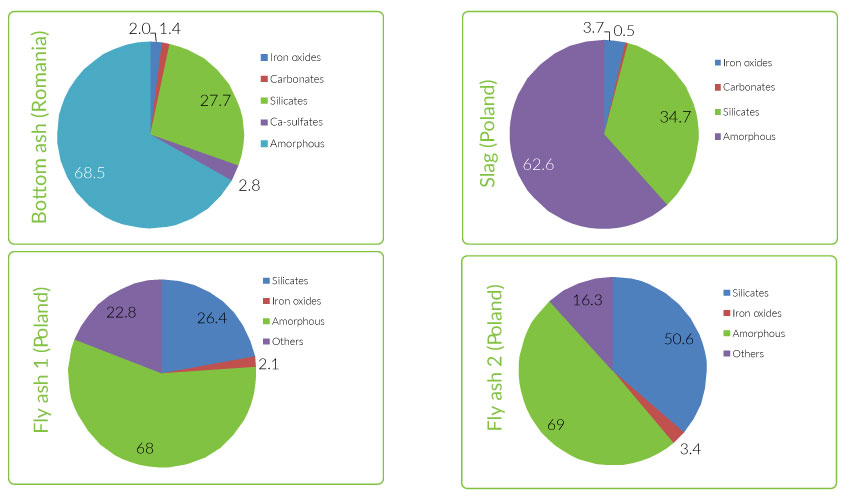

Ash mineralogy determined by XRD (wt.%; average values for p.f. samples)

Achieved results

Rezumat Etapa I 2015 si Etapa II 2016

Activitate.I.1.

UPB a elaborat un Studiu privind potenţialul de resurse secundare oferit de deseurile de combustie.

Activitate I.2. UCB şi CEO au elaborat fiecare anexe tehnice în care au prezentat informaţii despre: (i) sistemele de evacuare şi transport deşeuri rezultate în urma arderii lignitului în centralele pe lignit; (ii) localizarea geografică şi posibilităţi de acces pentru depozitele de zgură şi cenuşă pentru centralele termoelectrice din cadrul Complexului Energetic Oltenia; (iii) caracteristicile tehnice ale depozitelor de zgură şi cenuşă; (IV) suprafeţe de teren ocupate; (V) capacităţi de depozitare.

Activitate I.3: Au fost achizitionate in 2015 o serie de echipamente necesare in cadrul proiectului urmand procedurile legale si normele de achizitie interne ale UPB si UCB.

Activitate I.4: UCB şi CEO au elaborat anexe tehnice în care sunt descrise lucrările de (i) Prelevare a probelor elementare de cenuşă, (ii) Obţinerea probelor medii reprezentative, (iii) Prelevarea şi pregătirea probelor elementare de cărbune energetic. Probele reprezentative de cenuşă şi cărbune au fost transmise Partenerului UPB pentru efectuarea lucrărilor specifice de cercetare, conform Planului de realizare a proiectului.

Activitate I.5: A fost transmis in Portugalia numarul solicitat de probe pentru realizarea caracterizarilor prevazute in proiect.

Activitate I.6: UCB a elaborat Anexa tehnică în care sunt prezentate lucrările de sortare pe fracţii dimensionale a probelor medii de cenuşă, probele astfel sortate fiind transmise UPB.

Activitate II.1: UCB si CEO au evaluat cantităţile de CWP existente în depozitele istorice aparţinând CEO, situate atât în judeţul Gorj cât şi judeţul Dolj, şi au estimat cantităţile de CWP generate anual, pentru fiecare termocentrală în parte.

Activitate II.2: A fost realizate anexe tehnice privind resursele de carbuni si capacitatile de producere a energiei la nivel national, in perspectiva dezvoltarii unui proces de reciclare a cenusilor in vederea recuperarii HRM precum si motivaţiile şi concluziile selectării depozitului tinta. A fost creata o bază de date cu informaţii despre depozitele de CWP din jud. Gorj si din cadrul CEO.

Activitate II.3: A fost elabort un studiu de catre UPB, UCB si CEO care vizeaza evaluarea punctuala a citorva aspecte de interes pentru partenerul industrial, in perspectiva unei activitati ulterioare de exploatare a deseurilor existente in haldele istorice pentru extragerea metalelor grele si rare, precum si evaluarea implicaţiilor de mediu privind extragerea metalelor grele din depozitele de CWP in perspectiva dezvoltarii unui proces de reciclare a cenusilor si recuperarea HRM.

Activitate II.4: UCB a elaborat un studiu care releva: (i) Modificări ale compoziţiei chimice oxidice, în sensul diminuării conţinutului de Al2O3, Fe2O3, MgO, CaO şi K2O, (ii) Creşterea conţinutului de carbon rezidual, (iii) Conservarea caracteristicii de constanţă a proprietăţilor (densitate, distribuţie dimensională) pe întreg volumul depozitului CWP studiat.

Activitate II.5: UPB a elaborat un Raport stiintific privind prelevarea si pregatirea probelor pentru analiza tehnica si caracterizarea petrografica. Au fost efectuate determinari cantitative ale compozitiei petrografice pentru punerea in evidenta a compozitiei si evidentierea fazelor anorganice si organice. UPB a elaborat un raport de experimentare în care sunt prezentate lucrările de laborator efectuate.

Activitate II.5: UPB a elaborat un raport de experimentare privind caracterizarea probelor individuale de carbuni şi a amestecurilor, precum si a probelor de cenusa prin analize tehnice (umiditate, cenuşă, materii volatile, sulf total, carbon fix). Determinarea HRM in cenusa, aflata in responsabilitatea Partenerului P4 (Universitatea din Porto) s-a efectuat prin subcontractarea cu laboratorul acreditat pentru astfel de analize Bureau Veritas Commodities Canada Ltd. Vancouver BC V6P 6E5 CANADA. Au fost efectuate determinari cantitative ale compozitiei elementelor REE in carbuni prin analiza SEM/EDS. Au fost efectuate determinari cantitative prin analize ICP-MS a HRM si REE si au fost identificate si determinate 25 elemente de interes, cu punerea in evidenta a repartizarii distributiei acestora pe zone si pe adancimi. Au fost evaluate statistic rezultatele obtinute si a fost intocmit un raport stiintific.

Activitate II.7: UCB a caracterizat din punct de vedere al compoziţiei granulometrice toate cele 205 de probe elementare de cenuşă prelevate din Depozitul Valea Ceplea, obţinând valorile specifice selectate. CEO a asigurat caracterizarea fizică a umidităţii şi densităţii în vrac a tuturor probelor individuale de cenuşă. UPB, a evaluat rezultatele transmise de UP privind caracterizarea a 25 probe de cenusa din punct de vedere mineralogic (XRD), al compoxitiei oxidice (XRF), a compozitiei elementelor REE prin analiza SEM/EDS. Au fost identificate si determinate LAYSr ca elemente de interes, cu punerea in evidenta a repartizarii distributiei acestora pe zone si pe adancimi. Au fost evaluate statistic rezultatele obtinute si a fost intocmit un raport stiintific.

Activitate II.8: UCB a obţinut cantităţi reprezentative de cenuşă din care eşentioane reprezentative au fost transmise UPB. Au fost caracterizate probele de cenusa separate pe fractii granulometrice.

Activitate II.9: UPB a studiat cinetica solubilizării în acid azotic la diferite concentraţii şi temperaturi. S-a stabilit metoda optima tehnologic de extractie a elementelor utile din cenușă.

Activitate II.10: UPB a elaborat un studiu privind eficienta sistemelor de extractie propuse.

Activitate II.11: Au fost achizitionate mai multe echipamente de laborator necesare in cadrul proiectului cf. documentelor justificative aferente etapei de decontare II 2016. Dupa punerea in functiune a echipamentelor acestea au fost utilizate in cadrul laboratorului UPB-CPMTE.

Activitate II.12: UPB a elaborate un Raport privind activitatea de diseminare: despre deplasarea in strainatate, in care se prezinta informatii referitoare la simpozion/congres: denumire, perioada desfasurare, locul de desfasurare, programul evenimentului, titlul lucrarii care s-a prezentat, autorii. S-a participat la 2 intilniri in cadrul proiectului si 1 workshop. S-au publicat 6 lucrari de diseminare, in parteneriat care includ Brosura proiectului si pagina WEB a proiectului.

Rezumat Etapa 2017

Activitate III.1. S-a intocmit un studiu in care se prezinta punctual informații cu caracter general dar si privind situatia de la noi din tara din Bazinul carbonifer Oltenia și caracteristicile deșeurilor de ardere în ceea ce privește condițiile de prelucrare termochimica. Raportul prezinta particularitățile formării geologice a lignitilor din bazinului Olteniei cu repercusiuni asupra procesului de ardere în centrale electrice si relațiile dintre caracteristicile cărbunelui și cenușii.

Activitate III.2. UPB a elaborat o anexa tehnica in care se prezintă detaliat modul in care au fost alcatuite probele cumulate pe fractii granulometrice provenite de la Turceni si Govora si rezultatele caracterizarii fizico-chimice.

Activitate III.3: Se prezinta informatii din literatura privind justificarea metodelor alese si metodologia de extractie si recuperare a unor metale din medii apoase. Se prezinta procesul de extracție şi concentrare a metalelor Galiu (Ga) și Samariu (Sm) care a fost realizat în sistemul de microemulsie de tip Winsor II (microemulsie de tip apă-în-ulei, exces de apă) pe probe sintetice si experimentale de cenusa.

Activitate III.4: UPB a elaborat un studiu preliminar în care sunt descrise lucrările de evaluare a concentratiei elementelor tinta in probele supuse cercetarii. Totodata au fost efectuate trei serii de atac cu acizi concentrati si diluati. S-a efectuat un calcul tehnico- economic preliminar de estimare a costurilor de tratare a 100 g (laborator) si 10 t de cenusa (industrial).

Activitate III.5: CEO a asigurat prelevarea de probe, care au fost transmise UCB. UCB a asigurat inventarierea și marcarea probelor elementare de cenușă, respectiv pregătirea acestora pentru efectuarea testelor de laborator necesare determinării principalelor caracteristici fizice. Caracterizarea probelor reprezentative prin analiza tehnica a fost efectuata de UPB iar analiza chimica oxidica (majore, minore si REE) inclusiv prin metode petrografice a fost efectuata de partenerul UP (Universitatea din Porto). Se prezinta detaliat pe tipuri de probleme, contributia UPB si UP in ceea ce priveste metodele de analiza utilizate, rezultatele obtinute si consideratiile care au fost facute.

Activitate III.6: S-au preparat probele reprezentative in parteneriat de catre UPB si UCB.

Activitate III.7: UPB a elaborat un raport preliminar privind concentrarea elementelor tinta identificate prin metode chimice. Pentru precipitarea elementelor majoritare, care au influenţă mare asupra posibilităţilor de separare a elementelor utile din soluţia de extracţie, se propune metoda variatiei de pH.

Activitate III.8: UPB a elaborat un raport privind activitatea de diseminare: despre deplasarea in strainatate, in care se prezinta informatii referitoare la simpozion/congres: denumire, perioada desfasurare, locul de desfasurare, programul evenimentului, titlul lucrarii care s-a prezentat, autorii. S-a participat la 2 intilniri in cadrul proiectului si 1 workshop. S-au publicat 3 lucrari in Proceedings, s-au prezentat 2 lucrari la un congres, s-a transmis 1 lucrare la o revista cu factor de impact 5,4, in parteneriat.

Rezumat Etapa 2018 – Finala

Activitatea.IV.1. CEO a intocmit un studiu in care se prezinta rezultatele testelor efectuate pe probele de cenusa proaspat prelevata din producţia curentă a Sucursalei Electrocentrale Turceni (cca. 40 kg/probă) care au fost supuse caracterizării în laborator.

Activitate IV.2. UPB a elaborat un raport de experimentare in care se prezintă detaliat modul in care a fost testata adsorbtia fenolului, la nivel laborator, pe trei probe precursor sub formă granulară pornindu-se de la probele de cenusa inbogatite in carbon, provenite de la termocentrala Govora.

Activitate IV.3 si IV.5: UPB a intocmit un raport detaliat de experimentare laborator privind valorificarea diferitelor produse obținute, prin concentrare/precipitare, obtinerea de nanoparticule metalice oxidice pentru utilizare potentiala la fabricarea de precursori pentru colectori solari, si obtinerea de suporturi pentru fotocatalizatori.

UCB a intocmit un studiu privind utilizarea deșeurilor in amestecuri folosite în domeniul construcțiilor.

Activitate IV.4: UPB a elaborat un raport privind activitatea de diseminare in cadrul parteneriatului proiectului. S-a participat la 2 intilniri in cadrul proiectului si 1 workshop. S-au publicat 3 lucrari in Proceedings, s-au prezentat 2 lucrari la un congres, s-a transmis 1 lucrare la o revista ISI cu factor de impact 5,4 in parteneriat. Au fost elaborate trei (3) teze de doctorat, 2 (doua) in Polonia si 1 (una) in Romania si a fost elaborata o propunere de brevet de inventie in Polonia. Exista un (1) doctorand in stagiu in Romania.

Events and publications

2015

ERA-MIN Kick-off Meeting, 17-19/03/2015, Berlin

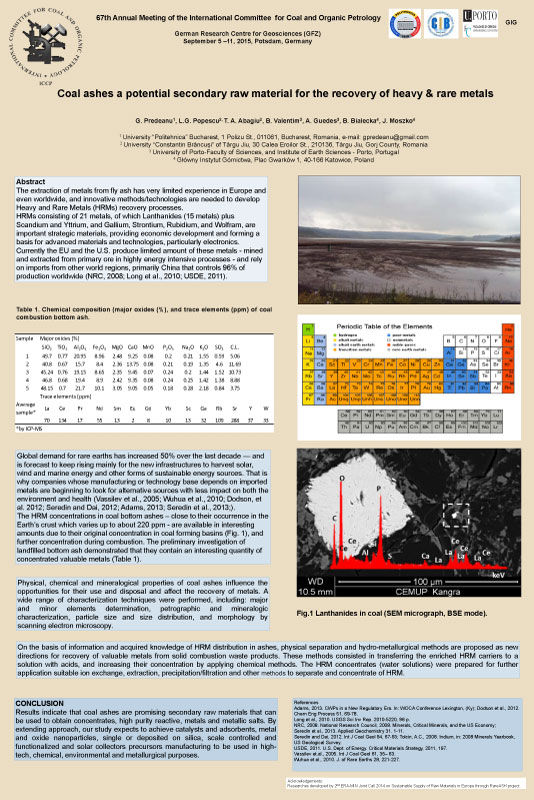

67th Annual Meeting of the International Committee for Coal and Organic Petrology, September 5-11, 2015, Potsdam, Germany (2 Posters)

1. Predeanu G., Popescu L.G., Abagiu T.A., Valentim B., Guedes A., Bialecka B., Moszko J. Coal ashes a potential secondary raw material for the recovery of heavy & rare metals. ICCP Program & Abstract Book. 67th Annual Meeting of the International Committee for Coal and Organic Petrology, September 5-11. 2015, Potsdam, Germany. Schriftenreihe der Deutschen Gesellschaft für Geowissenschaften Heft 87, 135-136. ISBN 978-3-510-49236-7.

2. Onose C., Ţane A., Mihaly M., Stamate D., Popa D., A., Rogozea A. Eco-friendly extraction of heavy and rare earth metals from combustion waste products - the kinetic study of the acid attack. ICCP Program & Abstract Book. 67th Annual Meeting of the International Committee for Coal and Organic Petrology, September 5-11. 2015, Potsdam, Germany. Schriftenreihe der Deutschen Gesellschaft für Geowissenschaften Heft 87, ISBN 978-3-510-49236-7.

2016

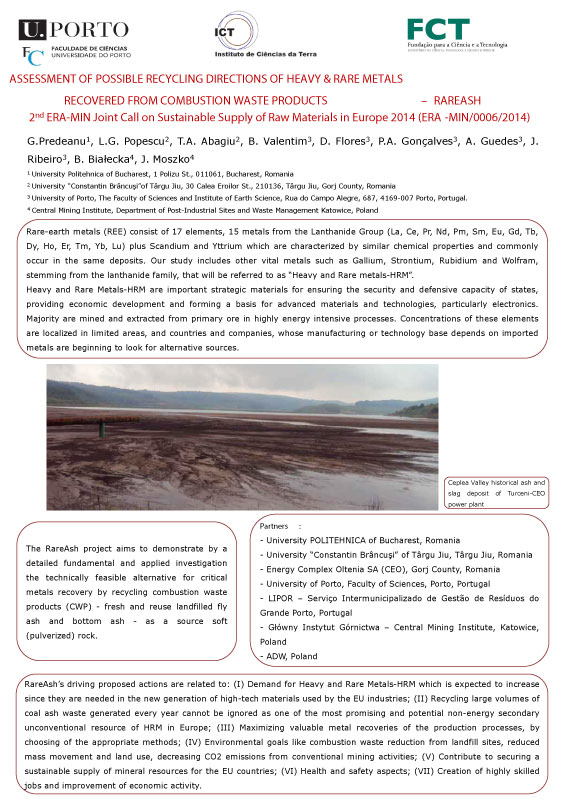

"Raw Materials University Day", Lisbon, Portugal. April 13, 2016 (Poster).

Rareash - Coordination and Technical Groups meeting, 6-8 June, University of Porto, Portugal

Rareash 1st Workshop, Black to Green using Gray“, June 7, 2016, University of Porto, Portugal

ERA-MIN Project Seminar Stockholm October 26, 2016 (Power Point presentations made by Bruno Valentim from the University of Porto).

Participation 11th International Conference on Energy & Environment (EE’16), Bern, Switzerland, December 17-19, 2016 http://iaras.org/iaras/journals/ijes

2017

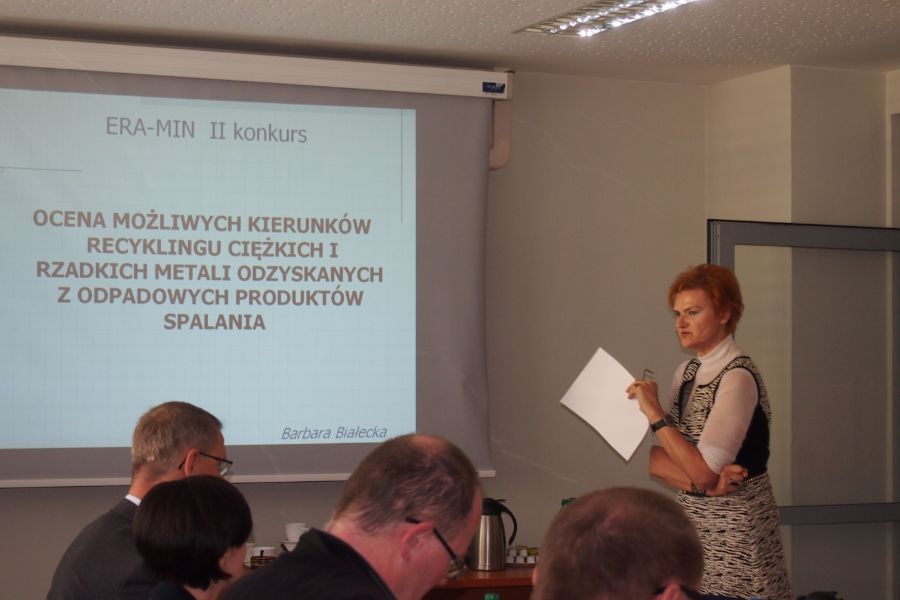

Rareash - Coordination and Technical Groups meeting and Workshop “Black to Green using Gray” (II), 22-26 May 2017, Central Mining Institute (Główny Instytut Górnictwa – GIG), Katowice, POLAND

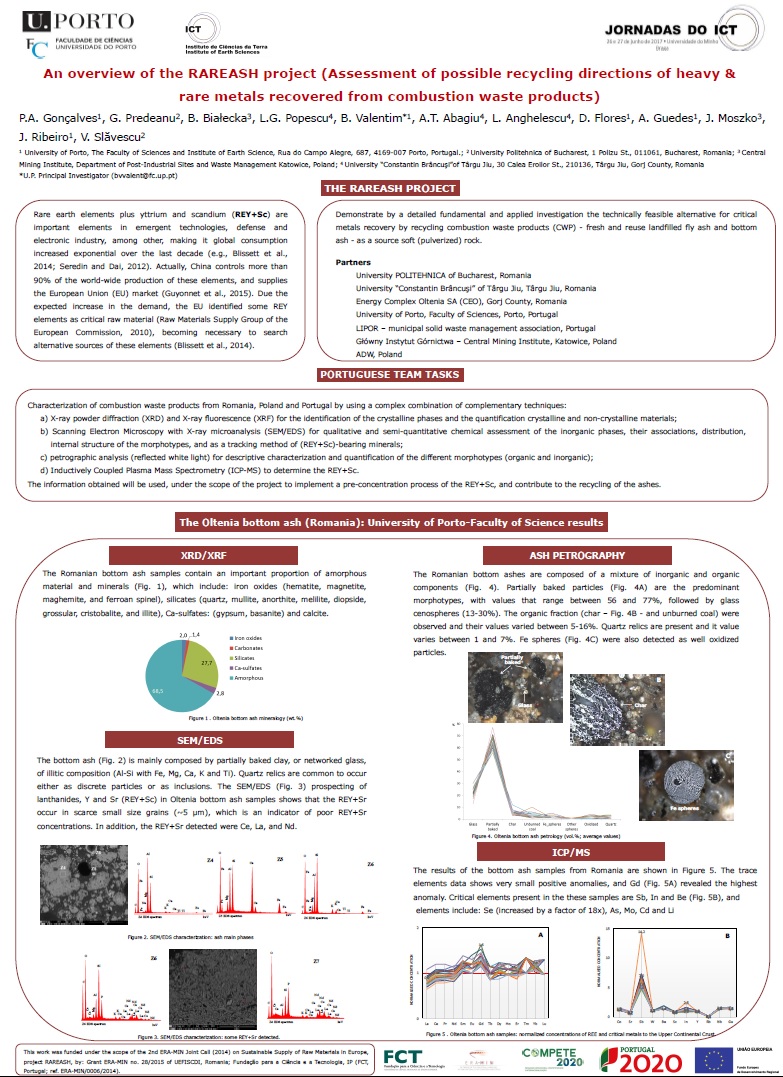

An overview of the RAREASH project (Assessment of possible recycling directions of heavy & rare metals recovered from combustion waste products). “Institute of Earth Sciences workshop 2017” 26-27 June, Braga, Portugal

GOLDSCHMIDT Conference, 13-18 August 2017 Paris, France: Oltenia (Romania) lignite bottom ash: a secondary raw material of REE and Y (REY).

The 69 Annual Conference of the International Committee for Coal and Organic Petrology (ICCP), 3-9 September 2017, Bucharest, Romanian Academy Library, Romania

2017 - Participation to different scientific events of the Polish team members of the Central Mining Institute (Główny Instytut Górnictwa – GIG), Katowice, POLAND

2018

Rareash - Coordination and Technical Groups meeting and Workshop “Black to Green using Gray” (III), 3-6 October 2018, University “Constantin Brâncuşi” of Târgu Jiu (UCB) and visit to Turceni Power Plant (CEO)

CARBON Conference, Madrid 1-6 July, 2018.

B. Valentim, A. T. Abagiu, B. Bialecka, A. Guedes, P. Gonçalves, J. Caluz-Moszko, L. Popescu, G. Predeanu, C. Santos, V. Slavescu. Coal bottom ash recycling for rare earth elements recovering for solar collectors precursors application. Poster 0312.

WSEAS CONFERENCE on ENVIRONMENT and DEVELOPMENT, London 26-28 October, 2018.

B.Valentim, P. Gonçalves, A. Guedes, L.G. Popescu, G. Predeanu. Petrographic and SEM/EDS characterization of bottom ash fractions obtained using magnetic separation equipment. WSEAS TRANSACTIONS on ENVIRONMENT and DEVELOPMENT, Volume 14, London 26-28 October, 2018, 526-530, E-ISSN: 2224-3496 526.

International Multidisciplinary Scientific GeoConference Wienna, 1-6 December 2018, Wienna, Austria ISI Proceedings

A. KLUPA, Z.ADAMCZYK: SPINELS IN THE FLY ASH OF POWER PLANT OSTROLEKA (POLAND), 18th International Multidisciplinary Scientific GeoConference SGEM 2018, 1-8.

PUBLICATIONS 2017

Gonçalves, P.A., Predeanu, G., Białecka, B., Popescu, L.G., Valentim, B., Abagiu, A.T., Anghelescu, L., Flores, D., Guedes, A., Moszko, J., Ribeiro, J., Slăvescu, V., 2017. An overview of the RAREASH project. Assessment of possible recycling directions of heavy & rare metals recovered from combustion waste products. Jornadas do ICT, 26-27 June, Universidade do Minho. Book of abstracts, pp. 25. ICT – INSTITUTO DE CIÊNCIAS DA TERRA. http://www.ict.org.pt/

“Institute of Earth Sciences workshop 2017” 26-27 June, Braga, Portugal An overview of the RAREASH project (Assessment of possible recycling directions of heavy & rare metals recovered from combustion waste products). P.A. Gonçalves, G. Predeanu, B. Białecka, L.G. Popescu, B. Valentim, A.T. Abagiu, L. Anghelescu, D. Flores, A. Guedes, J. Moszko, J. Ribeiro, V. Slăvescu.

PUBLICATIONS 2018

L. G. Popescu, F. Grofu. Capitalization of industrial wastes in economic circuit – a way to reduction the impact upon environment due to its storage. Fiabilitate si Durabilitate - Fiability & Durability, Editura “Academica Brâncuşi”, Târgu Jiu, No 1/ 2018, 327-332. ISSN 1844 – 640X.

L. G. Popescu, R.G. popa, E.C. Schiopu. The thermal power plant impact on the environment and some possibilities of reducing it by ash and slag recycling and reuse. Scientiffic. Papers Series E. Land Reclamation, Earth Observation & Surveing, Env. Engineering, Vol. VII, 2018, 10-15, ISSN 2285-6064.

ISI paper:

B. Valentim, A.T. Abagiu, L. Anghelescu, D. Flores, D. French, P. Gonçalves, A. Guedes, L.G. Popescu, G. Predeanu, J. Ribeiro, V. Slăvescu, C.R. Ward. Assessment of landfilled Oltenia lignite bottom ash (Romania) as a source of rare earth elements. International Journal of Coal Geology, Accepted for publishing.

Research and scientific knowledge transfer by education and patenting: were elaborated three doctoral theses, two in Poland and one in Romania

Poland:

1. Henryk Świnder: „Ocena możliwości otrzymywania metali ziem rzadkich z odpadów energetycznych” („Assessment of possibilities of rare earth elements from energy wastes”); opening of the doctoral dissertation: 29.06.2016r; closing of the dissertation: 05.2018.

2. Agnieszka Klupa: „Ocena zawartości surowców krytycznych w polskich popiołach lotnych” („Evaluation of critical material content in Polish fly ash”); opening of the doctoral dissertation: 29.06.2016r; closing of the dissertation: 03.2018.

Romania:

1. Daniela Cadar: “Îndepărtarea poluanților prin extracție în fluide nanostructurate complexe” (“Pollutants removal by extraction in complex nanostructured fluids”); opening of the doctoral dissertation: sept. 2016; closing of the dissertation/public session, 15.11.2018.

2. Alina Trentea: “Utilizarea microemulsiilor pentru valorificarea deseurilor” (“Use of microemulsions for wastes valorisation”). Opening of the doctoral dissertation: sept.2018.

Patent in Poland:

ODZYSK METALI ZIEM RZADKICH Z POPIOŁÓW („RECOVERY OF RARE EARTH ELEMENTS FROM ASHES) P.423021, 2017

Dissemination of the Rareash project

2015-2018 and beyond

2015

67th Annual Meeting of the ICCP, September 5-11, Potsdam, Germania

- Predeanu G., Popescu L.G., Abagiu T.A., Valentim B., Guedes A., Bialecka B., Moszko J. Coal ashes a potential secondary raw material for the recovery of heavy & rare metals. ICCP Program & Abstract Book. 67th Annual Meeting of the International Committee for Coal and Organic Petrology. Schriftenreihe der Deutschen Gesellschaft für Geowissenschaften Heft 87, 135-136. ISBN 978-3-510-49236-7.

- Onose C., Tane A., Mihaly M., Stamate D., Stamate, Popa D., A., Rogozea A. Eco-friendly extraction of heavy and rare earth metals from combustion waste products - the kinetic study of the acid attack. ICCP Program & Abstract Book. 67th Annual Meeting of the International Committee for Coal and Organic Petrology. Schriftenreihe der Deutschen Gesellschaft für Geowissenschaften Heft 87, 129-130. ISBN 978-3-510-49236-7.

2016

Raw Materials University Day, Lisboa, Portugal,13th April 2016, (POSTER)

G.Predeanu, L.G. Popescu, T.A. Abagiu, B. Valentim, D. Flores, P.A. Gonçalves, A. Guedes, J. Ribeiro, B. Białecka, J. Moszko. Assessment of possible recycling directions of heavy & rare metals recovered from combustion waste products.

11th WSEAS International Conference on Energy & Environment (EE’16), Bern, Switzerland, December 17-19, 2016

Popescu L., G., Abagiu A.T., Marica M., Anghelescu L., Predeanu G., Valentim B. New possibilities for conservation of natural resources by high capitalization of energy industry wastes, (published in 2017)

Articles:

J. CAŁUS MOSZKO, B. BIAŁECKA, M. CEMPA-BALEWICZ, H. ŚWINDER: EVALUATING THE POSSIBILITIES OF OBTAINING INITIAL CONCENTRATES OF RARE EARTH ELEMENTS (REES) FROM FLY ASHES. Metalurgija, 2016, 55, 4, 803-806.

Project’s Brochure, 20 pag. A5, 300 copies

Project’s WEB page: www.upb-cpmte/rareash

2017

Popescu, L.G., Abagiu, A.T., Anghelescu, L., Marica, M.M., Predeanu, G., Valentim, B., 2017. New possibilities for conservation of natural resources by high capitalization of energy industry wastes. International Journal of Environmental Science, 2, 1-6. https://www.iaras.org/iaras/filedownloads/ijes/2017/008-0001(2017).pdf ISI Proceedings

Articles in other journals:

- H. Šwinder, B. Biaĺecka, A. Jarosiński. Study on recovering the rare earth metals from fly ash by multi-stage leaching with sulfuric (VI) acid, Przemysł chemiczny, 2017, Vol.96, 11, 2236-2242.

- S. Želazny, H. Šwinder, B. Biaĺecka, A. Jarosiński. Recovery of rare earth elements from fly ash. Part 1. Leaching. Przemysł chemiczny, Vol.96, 11, 2017, 2279-2283.

- S. Želazny, H. Šwinder, B. Biaĺecka, A. Jarosiński. Recovery of rare earth elements from fly ash. Part 2. Precipitation. Przemysł chemiczny, 2017, Vol.96, 11, 2284-2290.

- J CAŁUS MOSZKO, B BIAŁECKA, M CEMPA-BALEWICZ, A. BAUEREK H: RARE EARTH ELEMENT CONTENT AND DISTRIBUTION IN ASH-SLAG MIXES DEPOSITED IN THE GARDAWICE LANDFILL, Inżynieria Mineralna – Journal of the Polish Mineral Engineering Society , 2017, 1, 103-110.

- L.G. Popescu, T. Abagiu, G. Predeanu, B. Valentim. Reduce of the thermal power plant impact upon environment by reuse of bottom ash as a source of raw materials for other industries. Annals of the “Constantin Brancusi” University Engineering Series, no.2, 2017, 21-26.

JORNADAS DO ICT, 26-27 June 2017, Universidade do Minho, Braga, Portugal

P.A. Gonçalves, G. Predeanu, B. Bialecka, L.G. Popescu, B. Valentim, A.T. Abagiu, L. Anghelescu, D. Flores, J. Ribeiro, V. Slavescu, A. Guedes, J. Moszko. An overview of the RAREASH project (Assessment of possible recycling directions of heavy & rare metals recovered from combustion waste products), 25.

GOLDSCHMIDT Conference, 13-18 August 2017 Paris

- Valentim B, Abagiu AT, Anghelescu L, Flores D, Gonçalves P, Guedes A, Popescu LG, Predeanu G, Ribeiro J, Slăvescu V., 2017. Oltenia (Romania) lignite bottom ash: a secondary raw material of REE and Y (REY). Abstract. Goldscmhidt2017 Conference. Poster comm. session 18d (gold2017:abs:3222).

17th International Multidisciplinary Scientific GeoConference SGEM 2017, June 27-July 06, 2017, Albena, Bulgaria ISI Proceedings

- A. KLUPA , Z.ADAMCZYK, A.HARAT: LANTHANIDES IN MINERAL ELEMENTS FOUND IN FLY ASHES FROM THE RYBNIK POWER PLANT, 17th International Multidisciplinary Scientific GeoConference SGEM 2017, Vol. 17, 883-888.

- H ŚWINDER, B BIAŁECKA,A. JAROSIŃSKI: RECOVERY OF RARE EARTH ELEMENTS FROM COAL COMBUSTION FLY ASHES, 17th International Multidisciplinary Scientific GeoConference SGEM 2017, Vol. 17, 973-978.

- M. CEMPA, B. BIAŁECKA, J. CAŁUS-MOSZKO, P. ŁATKA: RAREASH BASE – SUPPORT FOR RAW MATERIAL USE FROM ENERGY WASTE DEPOSITED ON LANDFILLS, 17th International Multidisciplinary Scientific GeoConference SGEM 2017, Vol. 17, 979-985.

- A. KLUPA , Z.ADAMCZYK, A.HARAT: SPINELS IN THE FLY ASH OF POWER PLANT RYBNIK (POLAND) 17th International Multidisciplinary Scientific GeoConference SGEM 2017, Vol. 17, 1051-1058.

- K. WIERZCHOWSKI , J. CAŁUS-MOSZKO, B. BIAŁECKA: PRELIMINARY ASSESSMENT OF THE POSSIBILITIES OF CONCENTRATING THE RARE EARTH METALS BY FLOTATION FROM THE POWER PLANT ASHES, 17th International Multidisciplinary Scientific GeoConference SGEM 2017, Vol. 17, 1125-1132.

69th ICCP Annual meeting, 3-9 September 2017, Bucuresti, Biblioteca Academiei Romane

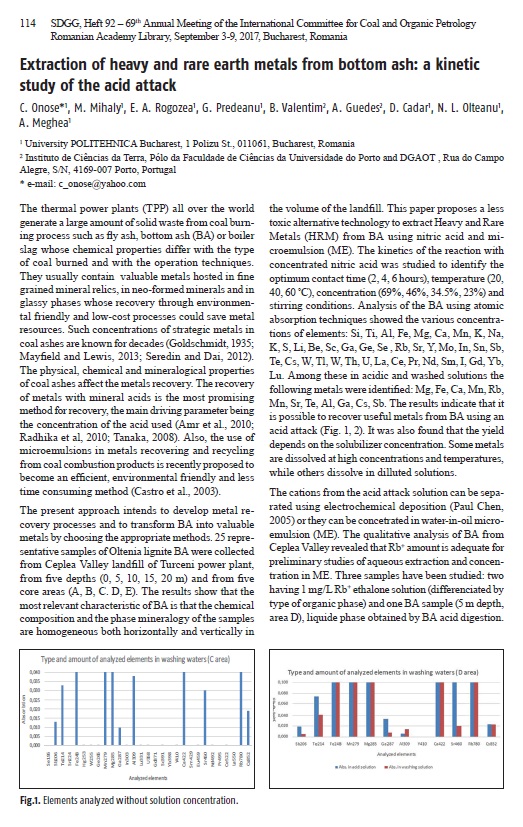

- C. Onose, M. Mihaly, E.A. Rogozea, G. Predeanu, B. Valentim, A. Guedes, D. Cadar, N.L. Olteanu, A. Meghea. Extraction of heavy and rare earth metals from bottom ash: a kinetic study of the acid attack. ICCP Program & Abstract Book. 69th Annual Meeting of the International Committee for Coal and Organic Petrology, September 3-9. 2017, Bucharest, Romania. Schriftenreihe der Deutschen Gesellschaft für Geowissenschaften Heft 92, 114-116. ISBN 978-3-510-49239-8.

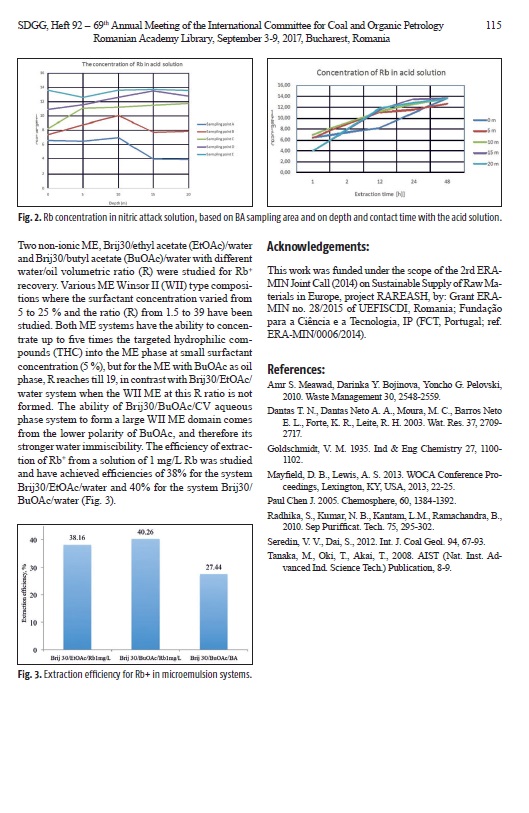

- B. Valentim, A.T. Abagiu, L. Anghelescu, D. Flores, D. French, P. Gonçalves, A. Guedes, L.G. Popescu, G. Predeanu, J. Ribeiro, V. Slăvescu, C.R. Ward. Assessment of landfilled Oltenia lignite bottom ash (Romania) as a source of rare earth elements. ICCP Program & Abstract Book. 69th Annual Meeting of the International Committee for Coal and Organic Petrology, September 3-9. 2017, Bucharest, Romania. Schriftenreihe der Deutschen Gesellschaft für Geowissenschaften Heft 92, 145-147. ISBN 978-3-510-49239-8.

International Multidisciplinary Scientific GeoConference Wienna Green 2017, 27-30 November 2017, Wienna, Austria ISI Proceedings

- B. BIAŁECKA, M. CEMPA, J. CAŁUS-MOSZKO: COMBUSTION WASTE LANDFILL SITES AS ALTERNATIVE SOURCES OF RARE EARTH ELEMENTS, Scientific Conference SGEM Vienna Green 2017, Vol.17/43, 51-58

- B. BIAŁECKA, M. CEMPA, J. CAŁUS-MOSZKO, A. BAUEREK: VARIABILITY OF RARE EARTH ELEMENTS CONTENT IN ASH AND SLAG DEPOSITED AT A LANDFILL SITE, Scientific Conference SGEM Vienna Green 2017, Vol.17/43, 275-282

2018

Articles in ISI journals:

B. Valentim, A.T. Abagiu, L. Anghelescu, D. Flores, D. French, P. Gonçalves, A. Guedes, L.G. Popescu, G. Predeanu, J. Ribeiro, V. Slăvescu, C.R. Ward. Assessment of landfilled Oltenia lignite bottom ash (Romania) as a source of rare earth elements. International Journal of Coal Geology, published

Articles in ISI journal (under preparation)

G. Predeanu, R. D. Mihalache, C.Onose, M. Mihaly, C. Lazăr, V. Slăvescu, B. Valentim, A. Guedes, A. Meghea, M. Bălănescu, B. Vasile. Methods for selection and separation of heavy and rare-earth metals from coal fly ash and bottom ash by acid leaching and microemulsion.

Articles:

- Z. Adamczyk, J. Komorek, M. Lewandowska, J. Nowak, B. Biaĺecka, J.-k. Moszko, A. Klupa. Ashes from bituminous coal burning in fluidized bed boilers as a potential source of rare earth elements. Mineral Resources Management, 2018, Vol.34, Issue 2, 21-36.

- L. G. Popescu, F. Grofu. Capitalization of industrial wastes in economic circuit – a way to reduction the impact upon environment due to its storage. Fiabilitate si Durabilitate - Fiability & Durability, Editura “Academica Brâncuşi”, Târgu Jiu, No 1/ 2018, 327-332. ISSN 1844 – 640X.

- L. G. Popescu, R.G. popa, E.C. Schiopu. The thermal power plant impact on the environment and some possibilities of reducing it by ash and slag recycling and reuse. Scientiffic. Papers Series E. Land Reclamation, Earth Observation & Surveing, Env. Engineering, Vol. VII, 2018, 10-15, ISSN 2285-6064.

CARBON Conference Madrid 1-6 Iulie, 2018 (POSTER)

B. Valentim, A. T. Abagiu, B. Bialecka, A. Guedes, P. Gonçalves, J. Caluz-Moszko, L. Popescu, G. Predeanu, C. Santos, V. Slavescu. Coal bottom ash recycling for rare earth elements recovering for solar collectors precursors application. Conferinta CARBON, Madrid 1-6 Iulie, 2018. Poster 0312.

WSEAS CONFERENCE on ENVIRONMENT and DEVELOPMENT, London 26-28 October 2018 ISI Proceedings

B.VALENTIM, P. GONÇALVES, A. GUEDES, L.G. POPESCU, G. PREDEANU. Petrographic and SEM/EDS characterization of bottom ash fractions obtained using magnetic separation equipment. WSEAS TRANSACTIONS on ENVIRONMENT and DEVELOPMENT, Volume 14, London 26-28 october, 2018, 526-530, E-ISSN: 2224-3496 526.

International Multidisciplinary Scientific GeoConference Wienna, 1-6 December 2018, Wienna, Austria ISI Proceedings

KLUPA, Z.ADAMCZYK:SPINELS IN THE FLY ASH OF POWER PLANT OSTROLEKA (POLAND), 18th International Multidisciplinary Scientific GeoConference SGEM 2018, 1-8.

Research and scientific knowledge transfer by education and patenting

Poland:

- Henryk Świnder: „Ocena możliwości otrzymywania metali ziem rzadkich z odpadów energetycznych” („Assessment of possibilities of rare earth elements from energy wastes”); opening of the doctoral dissertation: 29.06.2016r; closing of the dissertation: 05.2018.

- Agnieszka Klupa: „Ocena zawartości surowców krytycznych w polskich popiołach lotnych” („Evaluation of critical material content in Polish fly ash”); opening of the doctoral dissertation: 29.06.2016r; closing of the dissertation: 03.2018.

Romania:

- Daniela Cadar: “Îndepărtarea poluanților prin extracție în fluide nanostructurate complexe” (“Pollutants removal by extraction in complex nanostructured fluids”); opening of the doctoral dissertation: sept. 2016; closing of the dissertation/public session, 15.11.2018.

- Alina Trentea: “Utilizarea microemulsiilor pentru valorificarea deseurilor” (“Use of microemulsions for wastes valorisation”). Opening of the doctoral dissertation: sept.2018.

Patent in Poland:

ODZYSK METALI ZIEM RZADKICH Z POPIOŁÓW („RECOVERY OF RARE EARTH ELEMENTS FROM ASHES) P.423021, 2017

| Publication type | 2015 | 2016 | 2017 | 2018 | Total |

|---|---|---|---|---|---|

| ISI journal | 1 published 1 (under preparation) |

2 | |||

| ISI Proceedings | 1 | 7 | 2 | 10 | |

| Articles in national/international journals |

1 | 5 | 3 | 9 | |

| Conference Proceedings with Program Committee and review |

2 | 1 | 5 | 1 | 9 |

| Brochure | 1 | 1 | |||

| Webpage | 1 | 1 | |||

| Patents | 1 | 1 | |||

| PhD thesis completed/under preparation |

3 | 1 | 4 | ||

| TOTAL | 2 | 5 | 22 | 7 | 37 |

| TOTAL GENERAL | 37 |

| Publication type | Romania | Poland | Romania+Portugal Portugal+Romania |

Romania+Portugal+Poland | |

|---|---|---|---|---|---|

| ISI journal | - | - | 2 | - | |

| ISI Proceedings | 1 | 8 | 1 | - | |

| Articles in national/international journals |

2 | 6 | 1 | - | |

| Conference Proceedings with Program Committee and review |

1 | - | 3 | 5 | |

| Brochure | - | - | - | 1 | |

| Webpage | - | - | - | 1 | |

| Patents | - | 1 | - | - | |

| PhD thesis completed/under preparation |

2 | 2 | - | - | |

| TOTAL | 6 | 17 | 7 | 7 | |

| TOTAL GENERAL | 37 |

Partners

University POLITEHNICA of Bucharest (UPB) is the largest and oldest technical university in the country and among the most prestigious universities in Romania, and in South-Eastern Europe. The tradition of our institution has been developed in over 190 years through the effort of the most important nation's schoolmasters and of the generations of students. UPB is undergoing a continuous modernization process, being involved in a permanent dialogue with great universities in Europe and all over the world (www.upb.ro). At present, the University POLITEHNICA of Bucharest is formed by 15 different faculties, being full member in several European and international academic organisations CESAER, IAU, EUA, AUF.

The Faculty of Applied Chemistry and Materials Science goes back to 1867 when Chemistry courses were introduced and taught by Professor Emanuel Bacaloglu in the former School of Bridges, Roads and Mines. The faculty is located in the Polizu buildings built starting with 1886, its domain being ranked among top 100 in the world (www.chim.upb.ro). Besides the courses for the Bachelor's degree, there are Advanced Studies for engineers as well as postgraduate academic schools, etc. Every two years, the faculty supervises The National Conference on Chemistry and Chemical Engineering, taking an active part in the national and overseas scientific publications.

UPB - CPMTE is a non-governmental, non-profit, self- financed unit founded in UPB in 1998, under the frame of EU Tempus Program. Its main objective is developing R&D&I activities in environmental protection and bio-, nano-technologies. As main priority research area of CPMTE are: developing advanced eco-friendly technologies and methods for pollution control in environmental factors and food contamination, research for replacing synthetic chemicals by natural bioactive principles, developing of so-nanotechnology techniques for obtaining new multifunctional materials and nano-structures applied in environmental protection, nutrition, cosmetics, pharmaceutics, optoelectronics, biophotonics and cultural heritage preservation, quality control of chemical products, coal combustion products, food, biomaterials. Some quantifiable results during the last 5 years: over 70 papers published in ISI journals, 2 patents, 7 national and 7 international projects coordinated.

The main contribution of P1 –UPB in this project will be:

i) experimental models for sampling and characterization of raw materials;

ii) analytical solutions for HRM separation and processing by several extraction techniques;

iii) synthesis and characterization of high purity reagents, metals and metallic salts, novel nanostructured metal oxides catalysts on various supports;

iv) dissemination of results by preparing scientific articles, patent application, market potential replication.

University "Constantin Brancusi" of Targu-Jiu is a state higher education accredited institution, established in 1992 which operates under the coordination of the Ministry of National Education and Scientific Research based on the principles of university autonomy and academic freedom. University "Constantin Brancusi” of Targu-Jiu assumed by the strategic plan: - a fundamental role in developing research and promoting scientific research and to the needs of society and connection to European trends;

- harmonization of educational process with European guidelines and adapting the educational offer to the labor market and demographic trends;

- enhancing institutional capacity, improving the quality of the educational prerequisite for the university;

- a strategic management approach in order to strengthen the institution's position on the regional and national development of cooperation with foreign universities and university academic programs at European and global level.

Priority directions of research undertaken by university are as follows:

- Recoverable resources in the context of globalization;

- Energy and Environment;

- Economics Development;

- Management development;

- Management and development change;

- Governance;

- Development actors;

- Development strategies - political power and development - cultural prerequisites of development.

The main contributions of P2 -UCB in this project will be:

i) experimental sampling and characterization of raw materials;

ii) preliminary preparation of the ashes provided either from the industrial dump;

iii) dissemination of results by organising a workshop, preparing scientific articles, patent application.

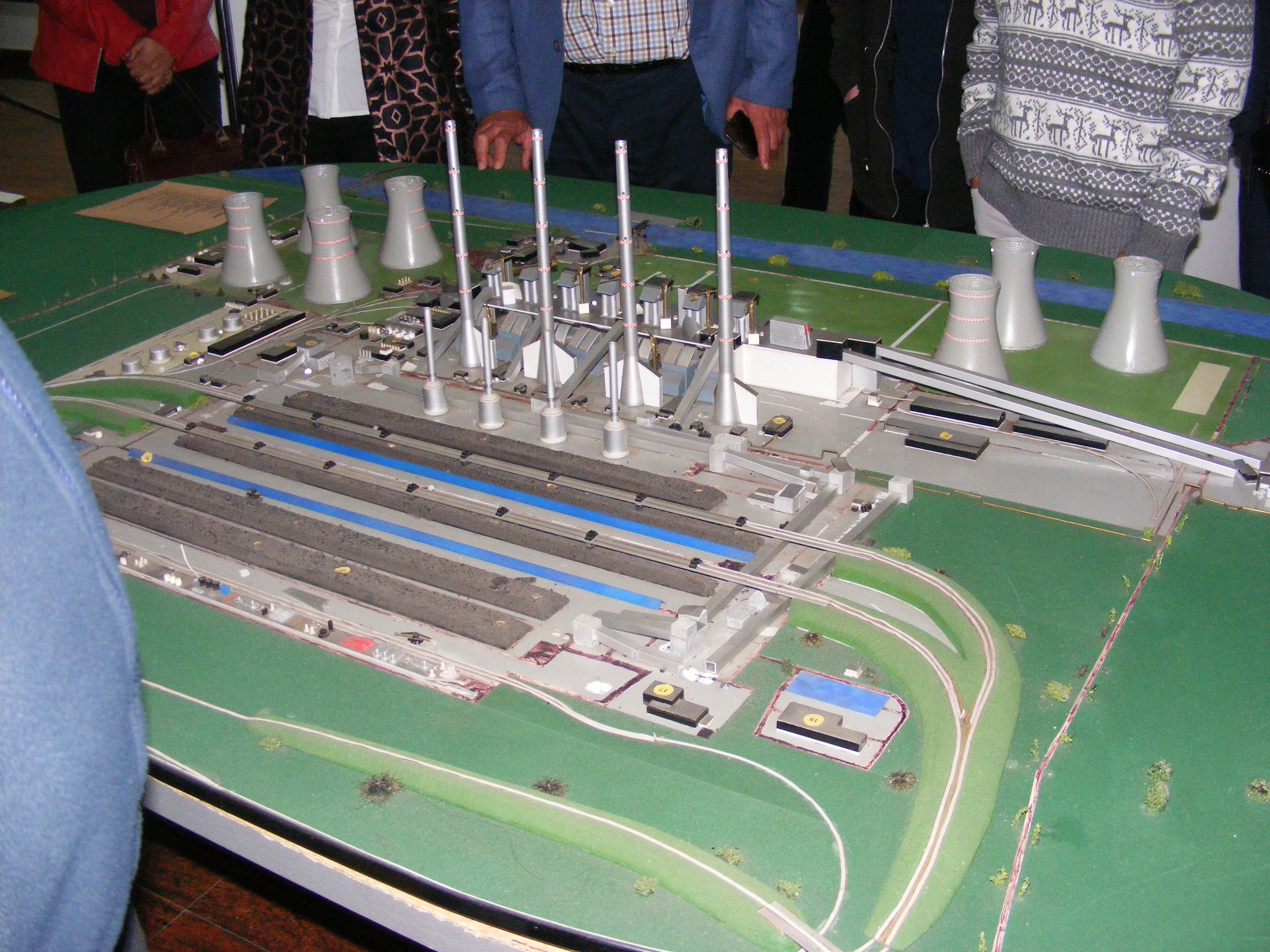

Number of employees: approx. 15,200: 5,200 employees - energy activity and 10,000 employees - mining activity

Object of activity: lignite - fired energy and thermal power generation; lignite extraction and preparation.

Production capacities: 13 power units with an installed capacity of 3900 MW and 134 high capacity mining equipment able to provide a production capacity of over 34 million tons of lignite per year distributed over 11 open pits with continuous flow extraction technologies. Energy market: In 2015, CE Oltenia achieved sales of electricity (98%), sales of thermal energy (2%), and provided approx. 3634 hGW ancillary services. In Romania, the power producers are divided according to the source of power generation, unlike the rest of the world, where there is only a mixture of sources to generate power

Complexul Energetic Oltenia offers: basic power in the National Power System; exploiting Oltenia lignite resources with maximum efficiency; safe energy - a significant factor of stability in the National Power System; the generation of energy is not depending on the atmospheric factors; efficient power; wide experience in the field of activity; efficient and reliable generation process by extending the lifetime of the existing production capacities; all 13 power units are qualified to provide ancillary services; 10 power units are qualified to provide Secondary Control; relatively cheap energy - the generation cost is below the average in the National Power System; clean energy - meeting all the environmental requirements. Complexul Energetic Oltenia is a major player on the local energy market and aims at becoming a significant player on the regional market through energy export at competitive prices.

WHY Complexul Energetic Oltenia? Provides safe power supply of consumers under conditions of random operation of the renewable power producers; Mitigates environmental impact and provides power efficiency due to the implemented projects; Is able to provide 30% of the power consumption in the national power system; Provides over 95% of the lignite production in Romania; Provides 15,000 jobs within the company and other 150,000 jobs outside the company; Able to be a major regional and European player

The main contributions of P3-CEO in this project will be:

i) inventory and mapping of the residue streams distribution within the selected sites;

ii) experimental sampling and physical characterization of ash samples;

iii) dissemination of results by participating to workshops, visit to ash deposits, preparing scientific articles, patent application.

The UP research team is being responsible for nearly one hundred years of research in coal geology, and applied coal and coal combustion products characterization, and also by university level education. Its actual staff composition includes university professors that always include academic and practical education in its research activities: new themes to its curricula; dissemination activities (workshops, seminars, etc); and, advanced formation opportunities to undergraduate, graduate, masters, and students.

The UP team also incorporates highly motivated and specialized researchers in the field of fly ash and boom ash, and transformation of mineral matter from coal combustion. They have skills in the utilization of advanced characterization techniques, e.g. Raman spectroscopy, Magnetic Susceptibility, Spectrophotometry, High Resolution SEM/EDS, QEMScan, and also in standardized sampling, sample separation techniques, and geochemical analysis of a wide range of geologic materials.

Additionally, due to its experience in research and “problem posing-problem solving” issues related to coal ashes, and its long date participation in the fly ash classification activities of the International Committee for Coal and Organic Petrology, the UP team complement this proposal consortium with its strategic vision and excellent skill of its researchers by proposing an out-of-box opportunity to short-circuiting the geosphere materials cycle.

The main contributions of P4 – UP – Faculty of Sciences of Porto University in this project will be:

i) complex characterization of raw materials;

ii) dissemination of results by organising a workshop, and preparing scientific articles.

Lipor has developed an integrated strategy for the recovery, treatment and confinement of MW, based on three main areas:

Multi-material Recovery, Organic Recovery and Energy Recovery, which are complemented by a Landfill where rejected and previously prepared waste is sent to. The Lipor Energy Recovery Plant processes 1000 tons of waste per day and produces 25 MWh of energy. The waste is burned at 1000- 1200°C producing energy, gases, dross and and ash. After inertization the ash is confined in the sanitary landfill. In the scope of its sustainable management strategy, Lipor has established a Quality, Environment, Safety, Social Accountability and Innovation policy, that should apply to every activity, product and service, including among others:

(i) To promote the implementation of a structured innovation process that reinforces corporate knowledge, promotes innovation and creativity and thus increases the value of the Organisation.

(ii) Education, training, information and knowledge sharing are key factors for this Policy, which contribute to LIPOR's sustainability and success.

The main contributions of P5 – LIPOR – Intermunicipal Waste Management of Greater Porto in this project will be the sampling of fly ash and boom ash from municipal solid waste incineration.

Created in 1945, GIG - Główny Instytut Górnictwa is a Polish governmental research institute engaged in problems of mining engineering, safety in mines and environmental protection in the hard coal mining sector

The multidisciplinary activities of the Institute comprise the following fields: mining engineering, geology and hydrogeology, geophysical engineering, combating natural and technical hazards in the mining industry, upgrading and utilization of minerals and reserves, monitoring and environmental protection in areas of mining exploitation, especially industrial waste management, certification of equipment and materials. GIG has extensive experience of acting as partner and coordinator of EU Programmes and RFCS projects. GIG has been involved in over 20 EU Programmes / RFCS RTD Projects over the last 10 years. GIG employs a staff of 586, including over 448 graduates, more than 112 of whom hold PhD or DSc degrees.

A part of the Institute constitutes the Experimental Mine “Barbara” established in 1925.

The main contributions of P6 – GIG – Central Mining Institute, Katowice Poland in this project will be:

i) experimental sampling and characterization of raw materials;

ii) preliminary preparation of the ashes provided from the industrial dump;

iii) complex characterization of raw materials;

iv) dissemination of results by organising a workshop, and preparing scientific articles.

The main contributions of P7-ADW, Poland in this project will be:

- dedicated reagents preparation, reagents improvements aer initial tests;

- dissemination of the results.

Contact

Project Manager: Dr. Georgeta PREDEANU

P1 - Coordinator: UPB - University POLITEHNICA of Bucharest, Research Centre for Environmental Protection and Eco-Friendly Technologies, Gh. Polizu St. 1, District 1, Code 011061 Bucharest ROMANIATel. +40213154193, Fax +40213154193; gpredeanu@gmail.com

Prof. Luminiţa Georgeta POPESCU

P2: UCB - University „Constantin Brâncuși” of Târgu Jiu, Târgu Jiu, ROMANIA, Calea Eroilor St. nr. 30, Gorj County, Code 210136Tel. +40253214307, Fax +40253215794; luminita.popescu69@gmail.com

Eng. Ionel Gabriel CHIRCULESCU

P3: CEO – Complexul Energetic Oltenia SA, 5 Alexandru Ioan Cuza Street, Târgu Jiu, Gorj County, ROMANIA, Code 210140Tel. +40253205401, Fax +40253227280; gabriel.chirculescu@ceoltenia.ro

Dr. Bruno VALENTIM

P4: UP - University of Porto, The Faculty of Sciences, Rua do Campo Alegre, S/N, 4169-007 PortoTel. +351 220402090, Fax +351 220402099; bvvalent@fc.up.pt

Ms. Elsa TEIXEIRA

P5: LIPOR – Serviço Intermunicipalizado de Gesãto de Resíduos do Grande Porto, Porto, PORTUGAL Address: Apartado 1510/4435-996 Baguim do MonteTel. +351229770100, Fax +351229756038; elsa.teixeira@lipor.pt

Prof. Barbara BIAŁECKA

P6: CMI - Central Mining Instute, Department of Post-Industrial Sites and Waste Management Katowice, POLAND, Plac Gwarków 1, Code 40-166 KatowiceTel. +48322581631, Fax +48322596533; bbialecka@gig.katowice.pl

Eng. Wojciech DUDEK

P7: ADW – Przedsiębiorstwo Przemysłowo-Handlowe Sp. z.o.o. “ADW” Wyry, POLAND, Zbozowa 2, Code 43-175 WyryTel. +48322187185, Fax +48323230085; wojtek@adw.com.pl